Overview

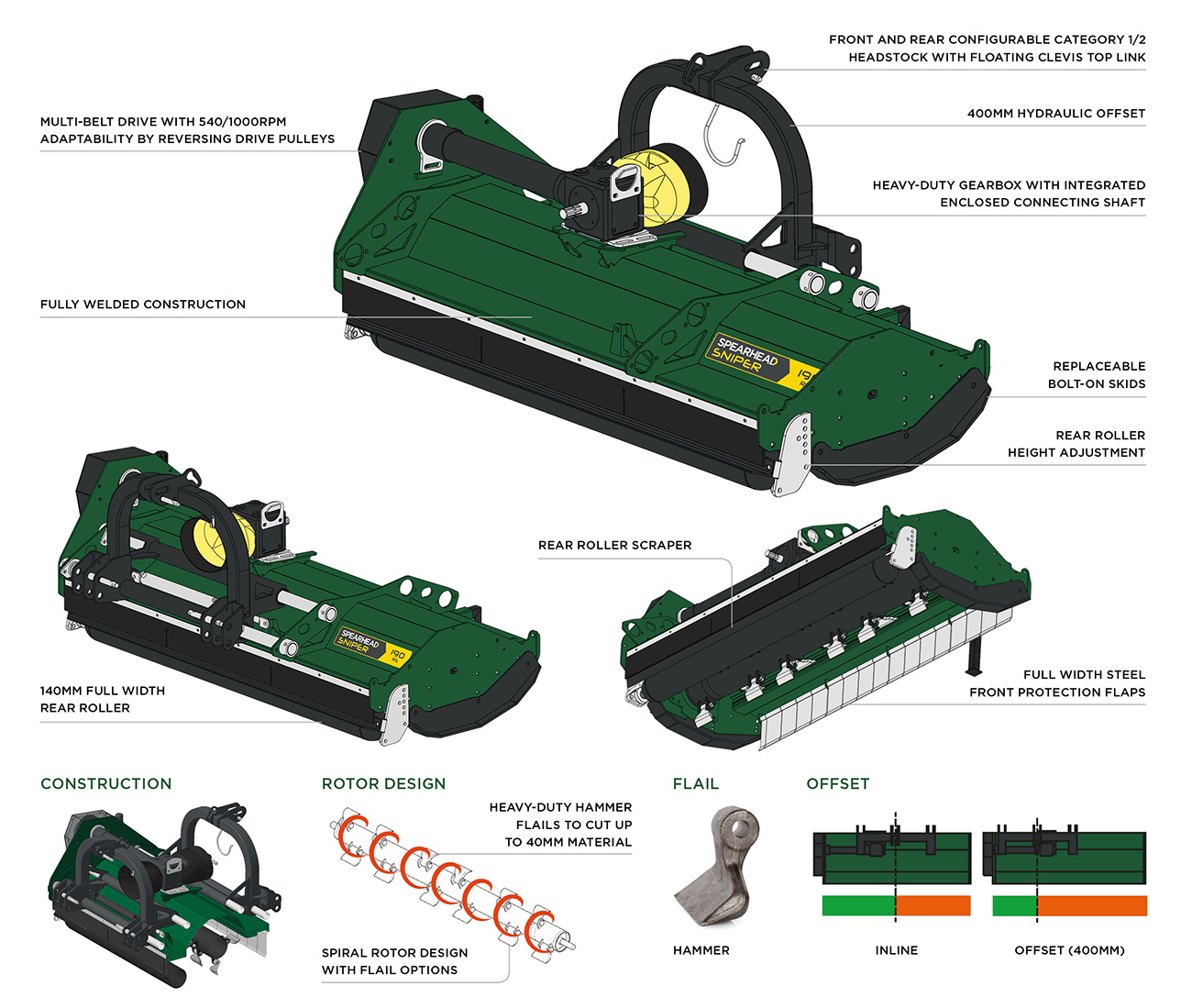

The Sniper RS brings the same features as the standard Spearhead Sniper with the added ability of being assembled for its operation front or rear mounted thanks to a cowl construction which allows for the headstock assembly to be fitted in two different ways.

This cost-effective machine can be attached to a wide range of prime movers with the addition of 400mm hydraulic sideshift ability allowing the machine greater access to cut in harder to reach farmland and pasture areas.

All Sniper RS machines come with a minimum of 24 hammer flails, operating at a high tip speed via a 540rpm input multi-belt driveline. This is combined with a 140mm full width adjustable, self-cleaning rear roller with scraper to ensure a professional, well distributed cut in material up to 40mm in diameter.

| AGRICULTURE |

| PASTURE |

| AMENITY |

| LIGHT SCRUB |

Specifications

**Top of cowl to floor

**Top of cowl to floor

**Top of cowl to floor